How strong is carbon fiber?

Carbon fiber stiffness and strength classification

The tensile modulus is defined as “the ratio of the stress along the axis (force per unit area) to the strain along the axis (the ratio of deformation to the initial length).” As long as the stress is lower than the tensile strength of the material, the tensile modulus can also be called the stiffness of the material, which can predict the elongation or compression of the material. Carbon fibers are classified based on the tensile modulus of the fibers. The unit of measure is a force pound per square inch of cross-sectional area, abbreviated as psi (or ksi for thousands of psi and MSI for million psi). Carbon fiber is classified in five categories: low modulus, standard modulus, medium modulus, high modulus, and ultra-high modulus.

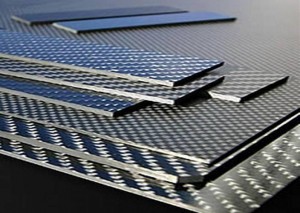

The stiffness and strength of a laminated carbon fiber epoxy sheet or plate is determined by the following factors:

-Material properties of carbon fiber

-Fiber placement schedule (fiber orientation, braid type and thickness of the laminate)

-Fiber/resin ratio

For a balanced, symmetrical 0/90 degree ply plan, a good estimate of the tensile modulus is 10 MSi (70 GPA). For the same layup, a good estimate of tensile strength is 87 KSI (600 MPA).

In comparison, steel has a tensile modulus of about 29 MSI (200 GPa) and a tensile strength of 61 KSI (420 MPA). Aluminium has a tensile modulus of approx. 10 MSI (69 GPa) and a tensile strength of 40 KSI (276 MPA)

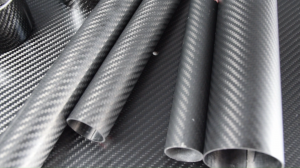

The hardness of ultra-high modulus carbon fiber is about 3 times that of standard modulus, but the strength is not as good as standard modulus. In addition, carbon fiber has excellent fatigue resistance compared to steel and aluminum. Similarly, when combined with the right resin, carbon fiber is one of the most corrosion-resistant materials on the market.

How does carbon fiber compare to other materials?

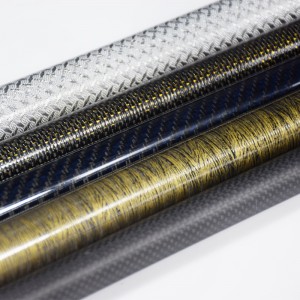

The density of glass fiber and Kevlar laminates is close to that of carbon fiber. However, carbon fiber is stronger and harder than glass fiber or Kevlar

Comparing the properties of carbon fiber with other materials is not always easy. There are multiple ways to measure intensity, which can make it difficult to make objective comparisons. However, when looking strictly at a particular tensile modulus and a particular tensile strength, it is clear that strength is not the top priority of every project. When selecting materials for a project, other factors such as flexibility or manufacturing requirements must often be considered. When strength, stiffness and weight are critical, carbon fiber is often the best choice.

Comparing the properties of carbon fiber with other materials is not always easy. There are multiple ways to measure intensity, which makes it difficult for us to make objective comparisons. However, when looking closely at the specific tensile modulus and the specific tensile strength, the choice is obvious.

Strength is not the top priority of every project. When selecting materials for a project, other factors such as flexibility or manufacturing requirements must often be considered. When strength, stiffness and weight are critical, carbon fiber is often the best choice.

Post time: Sep-30-2022